Exact Pack Machinery Sdn Bhd (EPM) was founded in 2000 by current Managing Director Mr. Ooi Hong Kheng draws on over 18-years of experience in packaging industry field. EPM is a marketing services company representing world renowned brands of packaging machinery.

EPM has a complete range and several of semi packaging machinery and auto packaging machinery to fulfill customers’ satisfaction. Technical competence, proactive client servicing and its ability to keep up with market needs allows EPM to provide value-added services to the customer. Therefore, EPM is committed to deliver high quality machine and reliable services for local and nation-wide customer.

EPM had supplied thousands of packaging machines across Malaysia and beyond to different sectors such as Food & Beverage, Chemical, Pharmaceutical, Health Care, Construction, Plantation and so on. EPM is well known of supplying quality products and after sales service at the competitive price.

What makes us different from our competitors?

Exact Pack Machinery Sdn Bhd

No 12, Jalan Sutera 1/5A,

Kawasan Perindustrian Bukit Angkat, 43000 Kajang,

Selangor, Malaysia

Phone / WhatsApp: +6012-612 6388

Email: yan_epm@yahoo.com

Copyright © EXACT PACK MACHINERY SDN BHD. All rights reserved.

Vacuum Machine Model: DZQ-400

Stand Alone Unit

Specifications:

Vacuum Single Chamber Machine Model: SC-450D

Specifications:

Remarks:

In order to do the ‘bricks-like’ form, one need to custom-made (Stainless Steel) boxes according to the plastic size, subjected to charges.

Vacuum Machine Model: DZQ-500

Stand Alone Unit

Specifications:

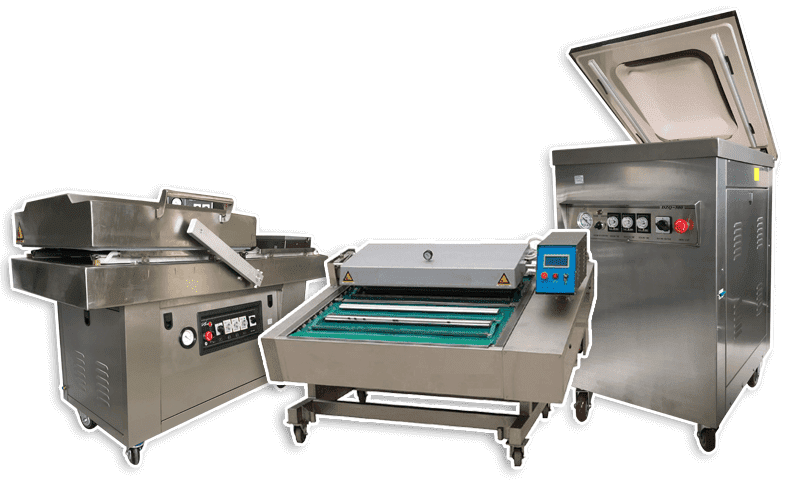

Double Chamber Vacuum Machine Model: DC-600

Specifications:

Double Chamber Vacuum Machine Model: DC-600-S

Specifications:

Single Chamber Vacuum Packaging Machine Model: SC-800-2 (Bush Pump)

Specifications:

Single Chamber Vacuum Packaging Machine Model: SC-800-4 (Bush Pump)

Specifications:

Continuous Vacuum Packaging Machine Model: TT-1090

Complete with Busch 160m³/hr pump.

Specifications:

Remarks

Pillow Type F.F.S. Machine Model: EPV-3220-PVS

Specifications:

Remarks

In case of the printed film, seal and cut position is controlled by the photo sensor. This photo sensor can only detect eye-mark in dark (Black) on the white base. Colour sensor is an optional item with extra charges

Every ONE unit of machine comes along with ONE set of volumetric cup & ONE former. For extra cup & former will be subjected to charges

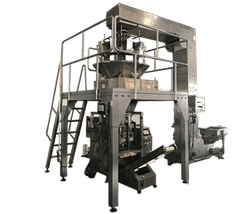

Fully Automated Solution for Free Flow & Granular Product – Pillow Bag Type

(A) Big Bag Pillow Type Model: EPV-4230-P

Specifications:

(B) Multi Head Weigher Model: AC-6B10-2B-1X (10 heads)

Specifications:

(C) Zigzag Type Conveyor Feeder

Specifications:

(D) Platform for Multi Head Weigher c/w leader (painted)

(E) Discharge Conveyor – Stainless Steel

Enquire now to find out more about our products and services.